Cornell Chemists use Sunlight to Upcycle Plastic into Benzoic Acid

A more sustainable and energy-efficient way of upcycling plastic waste with sunlight and oxygen

Upcycling is a good way to keep unwanted plastic out of the oceans and landfills. The process depends on an energy source to heat, melt, and further process upcycling. But what if that energy source is the Sun? Recently, chemists at Cornell University have found a sustainable way to upcycle plastic waste using sunlight and oxygen. In their latest experiment, they were able to upcycle polystyrene (PS), a type of plastic used to make various common items, into benzoic acid.

The resulting benzoic acid is a good item to be used in a high school and undergraduate chemistry laboratory. Besides that, it can also be used in making food preservatives, fragrances, and other products.

Upcycle plastic with sunlight

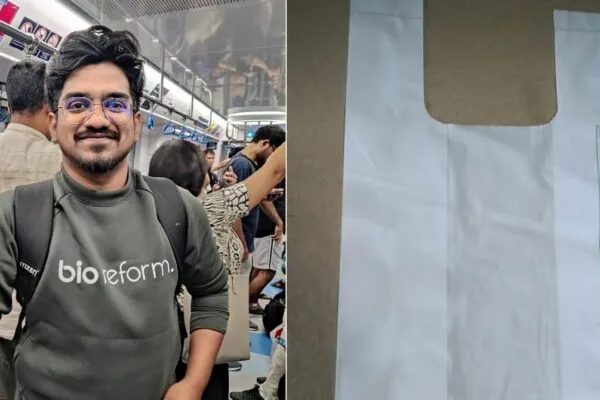

There are many common products consisting of polystyrene. Some of these objects, include hard plastic disc cases, Styrofoam egg cartons, and single-use drinking cups. All these products make polystyrene the third most common type of plastic found in landfill waste throughout the world.

Image: iStock

To address the issue of increasing plastic wastage, a research team led by Erin Stache, assistant professor of chemistry and chemical biology at Cornell, has invented a way that uses sunlight. This reaction can even form in a sunny window.

According to Stache, this new process is scalable, mild, and climate-friendly. With this new invention, she shared her lab’s mission to address environmental problems via chemistry. This process is even tolerant of different additives inherent in various consumer waste, including dyes, dirt, and other forms of plastic.

The benefit of using sunlight is that it gives you better control over the chemical processes, which are dependent on catalysts that otherwise need fossil fuel for energy. Using sunlight, one can eliminate the need for fossil fuels and the process can simply take place in any sunny location.

Efficiency of upcycling using sunlight

For testing the tolerance level of this process, the researchers used various products, ranging from coffee cup lids to packaging materials. During the test, they found that three items – Styrofoam, white coffee cup lid, and clear lid – efficiently degraded. However, the black coffee cup lid shows less degradation efficiency. It may be due to the presence of strong black dyes that prevent proper light penetration.

Nonetheless, the results show a good efficiency in breaking down PS at both small and large scales. After some more improvements, this process can become highly efficient commercially. It can even help in tackling the issue of plastic wastage in water streams.

Via: LabManager